Publish Rare Disease Research in F1000Research

12/08/2014Itinéraire d’un patient connecté (2) | Santé autrement magazine

14/08/2014Researchers Combine Ideas of 3D Printing With Molecular Self-assembly – Is Molecular Manufacturing Next?

What’s the ultimate extension of 3D printing technology? Where could 3D printing take us in the future? Eventually, we will have nano-factories, 3D printing at the molecular level. We will be able to turn our garbage into just about anything we want, via a sophisticated computer system, along with hardware capable of breaking any mass down to its molecular level, before using those molecules to construct a brand new object.

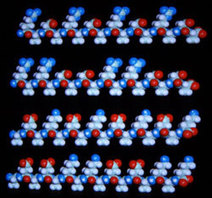

The two men have now combined the ideas of 3D printing with that of molecular self assembly to create a process which they call ‘genetic 3D printing’. For those who are not biologists, molecular self assembly is simply the process in which molecules arrange themselves in a particular order without guidance from an outside source. Molecular self assembly is a bottom-up approach like that of 3D printing. The discovery, which was accidental, allowed the researchers to create proteins which have the ability to self assemble into fibers. The discovery was made while they were simply trying to produce gluten adhesives, by cutting out a section of the gluten protein. What happened next surprised them. When the section of the protein was removed, fibers self assembled themselves in the beaker.

The quality of the fibers were on par with those produced by silk spiders, something which researchers have been trying to produce for years. Spider silk has a strength-to-weight ratio which is five times that of steel, making it an ideal material for all sorts of applications. The researchers went back and realized that they can manipulate the protein structures of the fibers to change their colors, but this wasn’t all. By combining the gluten protein with other proteins, they are able to molecularly print fibers with varying electrical properties, strengths and colors. In ordinary 3D printing, individuals use a software to translate a computer code and raw material into a physical object. In this case the researchers found that they were able to use a genetic blueprint as their computer code and back-calculate the DNA, which was inserted into a host bacterium, in this case e-coli. From there, the protein (raw material) grew, left the cell, and interacted with one another to build the fibers which the researchers had predetermined.

If this seems amazing, both Barone and Senger believe that they could eventually utilize this method as a way to molecularly manufacture all sorts of objects. Because the protein fibers are natural building blocks, once a method is figured out in which they are able to get the fibers to organize into larger structures, anything could be possible. From a coffee pot, to human bone, or even muscle, the researchers believe that one day this method of 3D printing fibers could manufacture it all. The researchers are currently working to further their discovery, and produce the silk-like fibers in large quantity for a variety of uses. Additionally they are looking for ways to increase the size of each fiber, eventually enabling the manufacturing of larger objects.

Source: 3dprint.com